Pipe Nomenclature Industry Standard

The difference between piping codes and piping standards can be summarized. The ASTM standards covers various types of steel pipes tubes and fittings for high-temperature services ordinary use and special applications such as fire protection use.

Ansi Asme A13 1 Pipe Labeling Requirements Graphic Products

Ansi Asme A13 1 Pipe Labeling Requirements Graphic Products

Below is a list of the most common abbreviations and terms found in the piping industry.

Pipe nomenclature industry standard. Standard pipe is used for low-pressure conveyance of air steam gas water oil or other fluids and for mechanical applications. 15052006 Is there a generally accepted naming convention for pipe specs or pipe classes. Standard for pipe fittings.

Cap end inserted into the end of tubing to dead-end the flow. Dimensions of the pipes are covered in following Standard ASME B3610 Welded and Seamless Wrought Steel Pipe Carbon. This refers to a family of standard screw thread types for interconnecting and sealing pipe ends by mating an external male with an internal female thread.

Pipe for use in the oil and gas industry are characterized by the American Petroleum Institutes API standard. Login to manage the site Authentication Provider. 01082014 British Standard 1710 the articles governing pipe labeling applies specifically and only to above ground or exposed pipes in and around the work environment and most generic piping on boats and industrial ships.

The identifications consist of up to 5 letters. I could always invent a system but dont want to re-invent the wheel when I dont have to. American Foundrymens Society AGA.

Refer to the table give below that summarized the available schedule numbers for carbon steel and stainless steel pipe based on ASME B3610 and B3619. The first identification letter is for the measured value the second is a modifier 3rd indicates passivereadout function 4th - activeoutput function and the 5th is the function modifier. I cant find a standard which covers this.

And others are the most common used. American Iron and Steel Institute ANSI. BSi - Pipe Tube and Fittings Standards and.

ASME B1647 covers two series A and B which represent large diameter applications. The pipe wall thickness has a variance of approximately 125. Standard Pipe Schedule as per ASME B3610 and B3619.

20042018 The International Institute of Ammonia Refrigeration IIAR is responsible for setting these standards for ammonia-carrying pipes. Some companies even publish their own internal piping standards based upon national and industry sector standards. American National Standards Institute API.

PIPING DIMENSIONAL STANDARDS Pipe sizes are documented by a number of standards including API 5L ANSIASME B3610M in the US and BS 1600 and BS 1387 in the United Kingdom. ASME 165 defines the ANSI flange the most commonly-used flange. Typically the pipe wall thickness is the controlled variable and the Inside Diameter ID is allowed to vary.

For Carbon Steel and Wrought iron Pipe as per ASME B3610 5 10 20 30 40 60 80 100 120 140 160 STD XS XXS. 06122018 Piping systems are generally designed on the basis of codes and standards. A fitting that connects pipes of different sizes.

Available in various shapes sizes and materials they are used to connect pipes. API 5L is the most widely recognized standard to which line pipe in the oil and natural gas industry is evaluated. 28042021 Primarily three standards govern pipe flanges.

Alloy Steel ASME B3619 Stainless Steel Pipe. This has been adopted internationally. Piping codes and standards from standardization organizations as.

ASTM International - Volume 0101 Steel - Piping Tubing Fittings. Codes and standard plays a very important role for the proper selection of specific material required in designing and construction of piping system. Furthermore BS 1710 says that their labeling is only required if the pipes are actively carrying fluids or gases.

An overview of the ASTM Volume 0101 standard. Ive been tasked to create a number of pipe specs or pipe classes that we can use on future small truck mounted skid type projects. American Petroleum Institute ASA.

American Gas Association AISI. Codes and standards helps us in the proper selection of specific material reduces cost inconvinence and confusion too. The standards set forth by IIAR requires facilities to label pipes carrying ammonia-based substances with the following information and color-coding.

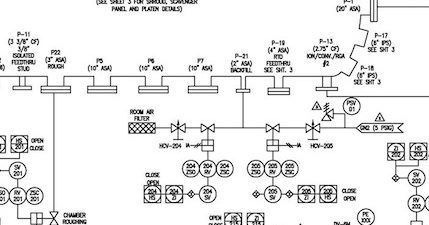

Series A flanges are heavier and. Based on STANDARD ANSIISA S51 and ISO 14617-6 the PID is used for the identification of measurements within the process. Primarily in machinery buildings sprinkler systems irrigation systems and water wells rather than in pipelines or distribution systems.

Since that is just a standard extra data is expected to ensure purchase orders are executed precisely. British Standard Pipe BSP is the UK.

Codes Standards And Recommended Practices The Process Piping

Codes Standards And Recommended Practices The Process Piping

Codes Standards And Recommended Practices The Process Piping

Codes Standards And Recommended Practices The Process Piping

Introduction To Piping System The Process Piping

Introduction To Piping System The Process Piping

P Id Symbols Complete List Pdf Projectmaterials

P Id Symbols Complete List Pdf Projectmaterials