Machine Control Relays Are Designed For Light Duty Industrial Applications

230V - 300V AC Adjustable Under Voltage. 18032014 Both AC and DC relays work on the same principle as electromagnetic induction but the construction is somewhat differentiated and also depends on the application for which these relays are selected.

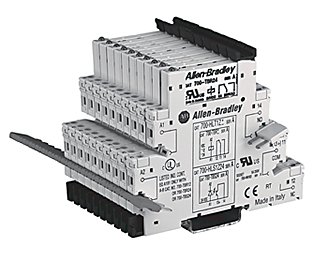

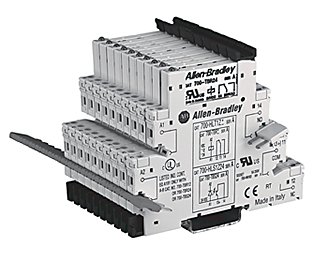

700 N Low Profile Industrial Relays Allen Bradley

700 N Low Profile Industrial Relays Allen Bradley

F T or F A control relay is designed to switch components on and off only when it receives a manual input.

Machine control relays are designed for light duty industrial applications. Used for the protection of various AC and DC equipment. Special design construction prevents flux from penetrating into the relay base housing. Time-delay crystal can latch-in differential resonant reed and power-type relays are the most common types of electromechanical relays used in industries.

Voltage control relays are designed to protect devices with sensitive operating voltage from damage caused by mains voltage. Motor control and automotive applications. DC relays are employed with a freewheeling diode to de-energize the coil and the AC relays use laminated cores to prevent eddy current losses.

Smart relays and PLCsPACs are simply programmed in software to control a machine or process while relays and timers must be connected by hardwiring to perform control logic. Heavy duty relays are often used for machine control and other industrial applications. A machine tool relay is a type standardized for industrial control of machine tools transfer machines and other sequential control.

The MR Mechanical Relay is a general purpose relay suitable for both low voltage and power switching. They are characterized by a large number of contacts sometimes extendable in the field which are easily converted from normally open to normally closed status easily replaceable coils and a form factor that allows compactly installing many. It also protects the circuit current.

The light-duty seal allows immersion cleaning of the printed circuit board. Conventionally the term machine tool relay is applied to NEMA-style relays. Also made of plastic this seal is used for relays that will be mounted to printed circuit boards.

As their name implies they are designed to control safety circuits and shut off primary power to a machine in the event. Electromechanical Relays have traditionally been used in machine tool control industrial assembly lines and commercial equipment. A control relay allows electrical current to flow through a conducting coil that opens or closes a switch.

There are three duty ranges for electromechanical relays including heavy at least 15 amperes medium two to ten amperes and light 2 amperes at most. It features a low power coil the 12VDC version requires only 100ma to energize. This type of relay cannot be immersion-cleaned.

In this article the term machine tool relay will be used interchangeably for both NEMA-style and IEC-style relays. When the relay is turned ON and OFF using a SCR the SCR serves as a half wave power source as it is and there are ample cases where the SCR is easily restored. Compare this product Remove from comparison tool.

These relay products are remotely actuated to control electrical power flow by either interrupting or completing an electrical circuit. What is Control Relay. The HPS Lighting Transformer is a cost effective approach to supply low voltage for recreational lighting light duty industrial and pool and spa applications or for a general purpose load including actuating relays bells control and low voltage circuits.

With a control relay users do not need to manually turn the switch to isolate or change the. Safety relays can be thought of as a cross between a relay and a controller. To control large power loads in industrial applications.

Here are some applications of electromechanical relays. They are made of durable long-lasting materials and are often used to control starters and other components. TE Connectivity TE has extensive capabilities in the design and manufacture of relays and a broad portfolio of switching solutions for demanding high performance applications.

T or F Machine control relays are designed for light-duty industrial applications. 01062020 It is slow because of the mechanical parts when compared to semiconductor-based relays. Today IEC relays often called control relays are also applied for the same purposes.

Relays designed for high voltage and high frequency applications are heavily insulated and use strong materials to increase contact life and withstand heavy use. A control relay is designed to switch components on and off only when it receives a manual input false A push-to-test pilot light allows the operator to. In this manner the relay operation and restoration timing are easily synchronized with the power source frequency and the timing of the load switching also is easily synchronized.

Relays are used to switch starting coils in contactors and motor starters heating elements pilot lights audible alarms and some small motors less than 18 HP. These relays can be ordered as complete devices in any pole combination up to a maximum of 12NO or 8NC and 4NO poles and are designed for use on machine tools process lines conveyors and similar automatic and semiautomatic equipment. The DPDT relay is rated at 10A 120VAC.

Each relay has an LED showing the low voltage status. A Control Relay is also known as a Relay is a switch an electromagnetic switch.

Nema Heavy Duty Relays Allen Bradley

Nema Heavy Duty Relays Allen Bradley

General Purpose Relays Allen Bradley

General Purpose Relays Allen Bradley

What Is A Control Relay Types Of Relays

What Is A Control Relay Types Of Relays

General Purpose Relays Allen Bradley

General Purpose Relays Allen Bradley